Boemar's unique colour system is customized to match our clients' corporate colours to provide brand uniformity across multiple surfaces.

We also revitalize a wide variety of building substrates after the original manufacturer's finish deteriorates, fades or delaminates.

Boemar provides these services on site safely, efficiently and at a fraction of replacement cost.

At Boemar we know the importance of surface preparation to ensure a durable, quality finish. Prior to applying our custom colour systems we use our proprietary products and processes to take the surface back to its original condition before proceeding with the application of the final colour system.

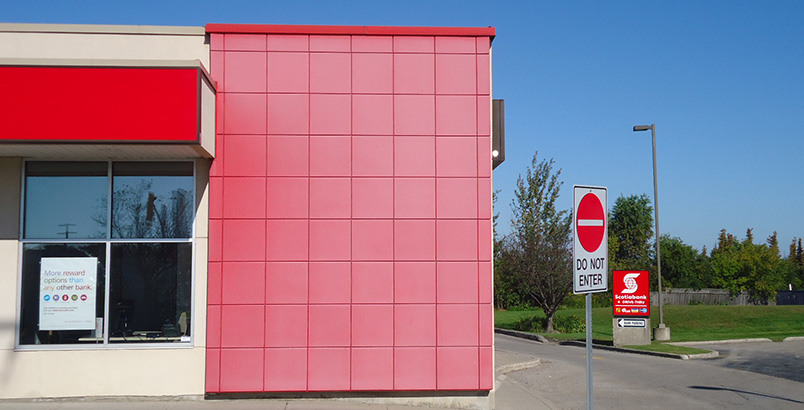

ACM

Aluminum composite materials delaminate and fade and there can be colour inconsistencies across the panels.

Whether we are rebranding or revitalizing ACM we consistently achieve a "porcelain-like" surface appearance that will surpass the surface longevity of most new products.

Block/Brick

We achieve a modernized high gloss finish on block & brick that matches our finish on surrounding substrates to provide a seamless appearance.

Unlike traditional paint which fades/peels, our versatile colour system offers both extraordinary long-term esthetic and substrate integrity. Our system contains unique repelling properties, which prevent dirt/residue from adhering or embedding into the surface, simply wiping clean.

Corrugated Metal

Traditional paint, inherent peeling, fading & general material deterioration are significantly reduced, as our system does not merely adhere to the surface, it fuses into the substrate, providing unparalleled protection against future delamination and fading. Our system is developed to client colour specification and results in a dramatic finish, while preserving the esthetic integrity of the substrate. The unique properties of this system prevent dirt/residue from adhering to the substrate, ensuring a simple clean.

EIFS/Stucco

Unlike traditional methods which merely adhere to the surface, our proprietary system embeds itself into the substrate, providing unparalleled protection against future deterioration and fading.

Our system eliminates inconsistencies in colour and is compatible with various stucco applications. The superior finish we achieve provides extraordinary long-term durability, while eliminating both inferior and costly repainting requirements.

FRP

Traditional methods to refurbish fibreglass reinforced panels require a controlled environment and as such, costly removal and replacement are the only option. Our system provides an unparalleled durable finish while ensuring superior protection and long-term substrate integrity. Moreover, it dramatically enhances the surface appearance and is installed to seamlessly match the surrounding substrate, on-site and at a fraction of replacement cost.

Boemar’s proprietary systems are also used to effectively remove built-up moss and dirt without damaging the original substrate. Further application of our custom colour systems dramatically increases the curb appeal of any site.

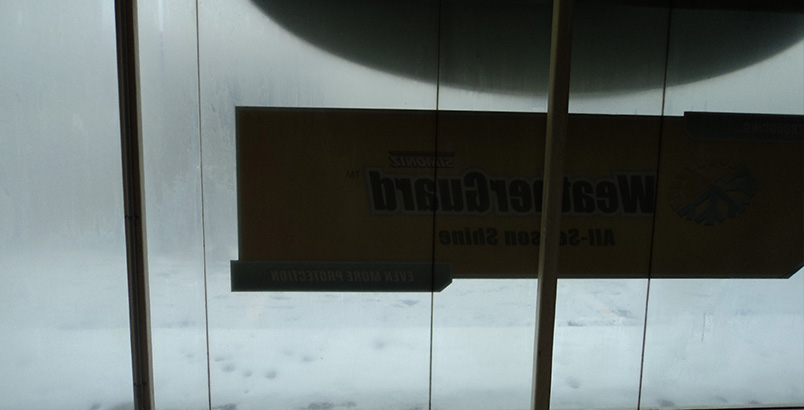

Glazing Calcium Removal

Traditionally windows with excessive calcium & chemical residue build up were often replaced at a significant expense. Boemar’s glazing system is unequalled in removing residue without scratching the surface or damaging the integrity of the glazing and provides a brilliant crystalline finish. The effectiveness of our systems result in a brighter and more appealing site experience for patrons.

Once the initial restoration has been completed an annual maintenance program will maintain the superior finish at a fraction of the initial amount.

Graffiti System (for easy graffiti removal by client)

Our system contains revolutionary properties, serving as a preventative measure against future damages.

The preventative component of this system is comprised of self-levelling properties which eliminate traditional inferior touched-up/patched methods that result in prevalent visual inconsistencies. Should this surface be further damaged or re-targeted with graffiti, the isolated area can be seamlessly repaired, without the need to resurface the entire substrate.

It is important to note that Boemar’s colour system will repel future graffiti when used in conjunction with proper graffiti removal procedures.

Grout System

Boemar’s proprietary tile & grout systems revitalize and restore the overall appearance of an area without the need for costly demolition or replacement, and with minimal business interruption.

Tiles can become extremely discoloured from years of deeply accumulated/embedded dirt. Our proprietary tile cleaners, together with our grout system make tiles look better than new. The result is a dramatic difference created by the application of Boemar’s unique processes & procedures and tiles can be easily cleaned months after the initial treatment. Once installed the revolutionary properties uniquely repel dirt, odours, residue and/or stains.

Our grout system can be custom colour matched to provide a seamless appearance with the tiles.

The need for harsh chemicals/cleaning products is eliminated and maintenance significantly reduced, as the only cleaning requirement is soap and water.

Rebranding

Boemar is synonymous with the revitalization of various building substrates during the rebranding process. Boemar creates custom colours per our client’s marketing specifications to provide seamless brand uniformity across multiple substrates, without the need to remove or replace the existing panels. The result is a "brand-new" modernized appearance, precisely reflecting new colour specifications and at a fraction of replacement cost.

Signage

Our sign refurbishment system dramatically enhances signage appearance, at a fraction of replacement cost. Once implemented, as it is comprised of unique fade resistant and debris repelling properties, dirt and residue will no longer adhere or embed into the surface and simply wipes clean.

The surface has a shiny, reflective appearance, with extra attention to detail, surpassing any within the industry and virtually eliminating the need for signage replacement. All work is completed on-site, with no business patron interruption during the process.

Soffit

Boemar is the solution for peeling and dirty canopy & building soffits. These areas become covered with years of built-up soil and vehicle exhaust leaving the site very unappealing to the consumer.

After using our proprietary products and processes to thoroughly remove the build-up from these areas, we apply our client’s custom colour system to provide a mirror-like finish which repels future accumulation, thereby maintaining the high-gloss and reflective quality for years.

Substrate Repairs

Cracked, blemished and broken panels distract from the overall appearance of a site. However, we can seamlessly repair these on site without the need to remove and replace the surrounding panels, resulting in considerable savings to the client. Our flawless repairs to ACM and FRP panels, to simply name a few substrates, are undetectable after the application of our client’s custom colour system.

Self-levelling properties contained within our systems eliminate the traditional inferior touch-up, patched inconsistencies. In the event that the surface is damaged an isolated area can be seamlessly repaired, without the need to resurface the entire substrate.